Why High-Performance Floor Coatings Are One of the Smartest Investments a Business Can Make

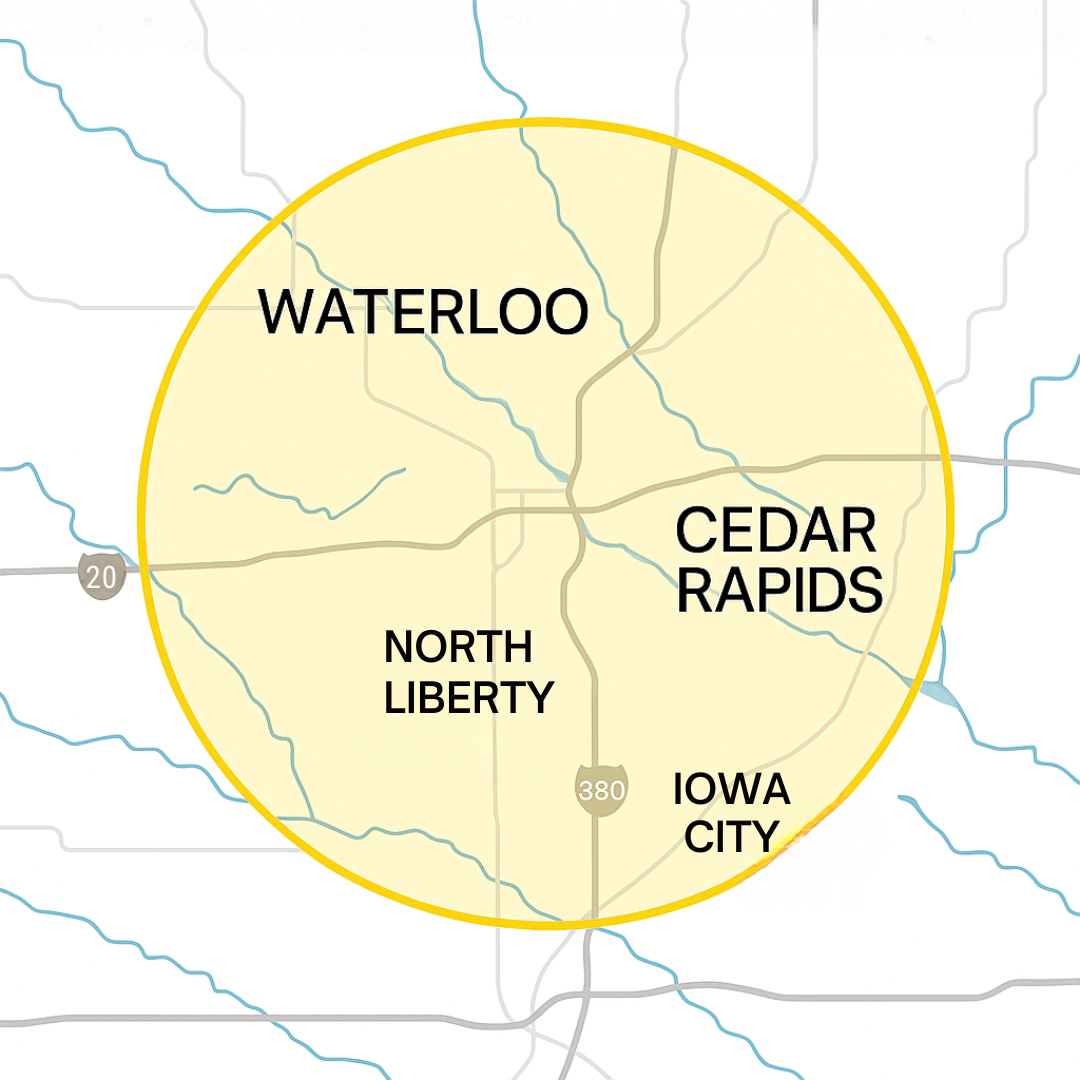

When most business owners think about improving their facility, they picture new equipment, layout upgrades, or operational efficiencies. But one of the most overlooked—and highest-return—investments you can make is right under your feet. At Revival Concrete Coatings, we’ve seen firsthand how a durable, professionally installed floor coating can dramatically lower long-term costs, reduce downtime, and extend the life of a facility. Whether you operate a warehouse, a retail store, a restaurant, or an industrial shop, the floor is the most used and most abused surface in your building. Protecting it isn’t just maintenance—it’s a strategic business decision. The Hidden Costs of an Unprotected Concrete Floor Bare concrete may seem tough, but it’s surprisingly vulnerable. Without a protective coating, businesses face ongoing expenses such as: Frequent repairs caused by cracking, spalling, and surface degradation Moisture-related problems, including mold, staining, and structural damage Safety hazards from uneven surfaces and worn areas Higher cleaning and maintenance costs Unprofessional aesthetics that impact customer perception and brand credibility A high-quality polyaspartic or epoxy system creates a long-lasting barrier that eliminates many of these issues—and in turn, cuts operational costs for years. Industries That Save the Most by Investing in Floor Coatings Some sectors see an especially strong return on coating their floors. Here’s why: 1. Warehousing & Distribution Warehouses experience heavy forklift traffic, pallet dragging, spills, and constant movement. A coated floor: Resists abrasion and impact Allows for faster cleaning and reduced downtime Increases surface brightness for a safer work environment Long-term savings: fewer slab repairs, fewer product-damage incidents, and improved employee safety. Industries That Save the Most by Investing in Floor Coatings Some sectors see an especially strong return on coating their floors. Here’s why: 1. Warehousing & Distribution Warehouses experience heavy forklift traffic, pallet dragging, spills, and constant movement. A coated floor: Resists abrasion and impact Allows for faster cleaning and reduced downtime Increases surface brightness for a safer work environment Long-term savings: fewer slab repairs, fewer product-damage incidents, and improved employee safety. 2. Automotive Shops & Dealerships Automotive facilities deal with chemicals, oils, hot tires, and heavy equipment. A coated floor: Protects against chemical staining and erosion Offers excellent slip resistance Enhances the showroom appearance Long-term savings: reduced damage from spills and heat, lower cleaning costs, and a more professional environment that supports higher sales. 3. Restaurants, Breweries & Commercial Kitchens These environments are constantly exposed to grease, moisture, and cleaning agents. A non-porous floor system: Prevents bacterial growth Meets health-code requirements Stands up to aggressive sanitization practices Long-term savings: fewer sanitation-related shutdowns, longer floor lifespan, and better customer safety. 4. Manufacturing & Industrial Plants Industrial operations put extreme stress on flooring. Coatings: Resist chemicals, abrasion, and constant motion Improve reflectivity to reduce lighting costs Provide custom safety striping and zone marking Long-term savings: fewer structural repairs, increased productivity, and improved OSHA compliance. The Tax Advantage: Floor Coatings as a Deductible Business Expense One of the biggest benefits many business owners miss is that commercial floor coatings typically qualify as a tax-deductible maintenance or capital improvement expense. Depending on your situation: Section 179 deductions may allow you to write off the entire investment in the first year. Bonus depreciation may apply for qualifying improvements. Repairs and maintenance often qualify as operational deductions. This means your project could cost significantly less after tax savings. Always consult with your tax professional, but the potential deductions make coatings one of the rare upgrades that improves both performance and your financial bottom line. Why Businesses Choose Revival Concrete Coatings At Revival Concrete Coatings, we specialize in commercial-grade systems engineered to last. Businesses trust us because we offer: Fast installation with minimal downtime UV-stable, non-yellowing polyaspartic technology High chemical and impact resistance Custom colors, textures, and safety striping Industry-leading warranties You invest in your people, your equipment, and your brand—your flooring deserves the same level of protection. Call Revival Today for Your Free Consultation