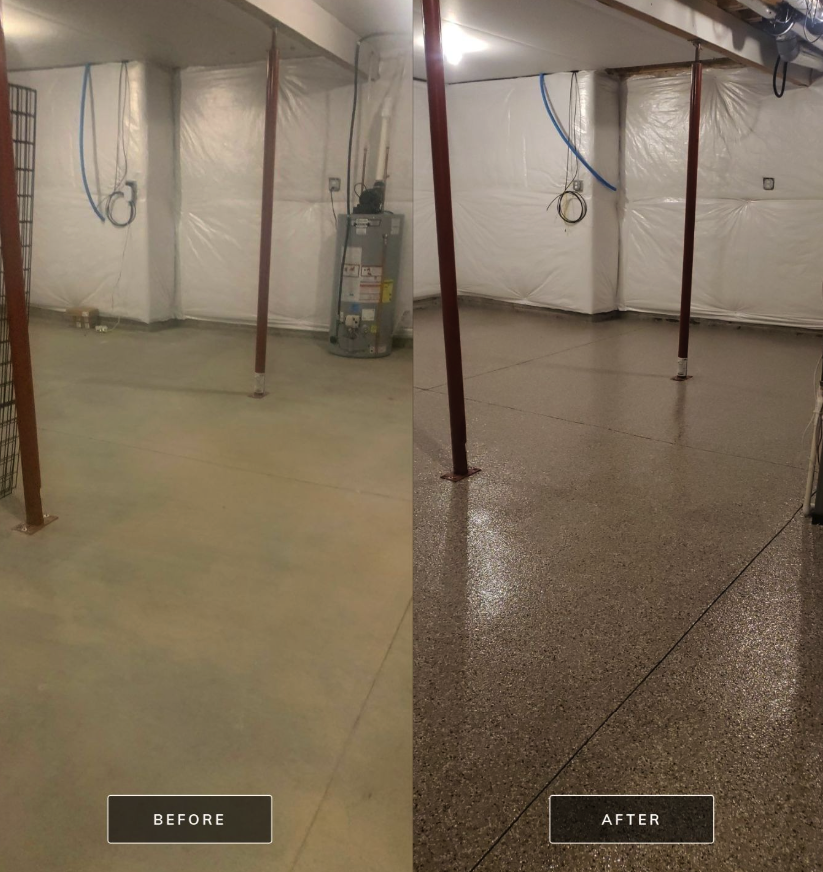

Upgrade your cracked, stained, and unsightly basement floors with our coating that is four times stronger than epoxy! Call us at Revival Concrete Coatings today.

A good basement is comfortable and functional. However, low-quality basement flooring can render your space less functional, aesthetically unappealing, and difficult to enjoy. At Revival Concrete Coatings, we provide long-lasting and stylish basement floor coatings to homes and businesses in Greater Des Moines and the Omaha Metropolitan area. Our solutions protect your concrete from harsh weather conditions and environmental damage, ensuring your basement remains a pleasant space.

Call today for a free quote!

Why Use Professional Basement Concrete Floor Coatings?

Being fully or partially underground, basements are susceptible to the growth of mold, moss, mildew, and moisture damage. These problems are prevalent in humid areas prone to storms. Concrete surfaces also tend to develop hairline cracks that increase in size over time.

Some benefits of our concrete basement floor coatings include:

- Low maintenance – Unlike epoxy floor coatings, our polyurea-polyaspartic solution is easy to maintain. You can use soapy water (no need for specialty cleaning products) to clean such floors and make them look as good as new.

- Moisture protection – Our polyaspartic coatings effectively resist moisture damage and the growth of mildew and mold.

- Slip-resistant finish – Traditional epoxy basement floor paint and other types of coatings become slippery when exposed to moisture. However, upon request, our polyaspartic floor sealer can provide good traction to prevent falls and slips even immediately after cleaning your basement floor.

- Improvement in property value – An upgraded concrete floor coating in your basement, featuring our polyurea coating system, can increase your home’s value.

Frequently Asked Questions

Find answers to commonly asked questions about concrete floor coatings.OUR SERVICES

Get Your Free Quote

"*" indicates required fields