Explore the six-step process to see how we turn your floors from blah to beautiful.

GRIND IT

Profile, repair, & vacuum the concrete surface to ensure the strongest adhesion possible.

REPAIR IT

We apply 100% solids polyurea mender to patch up any cracks in the concrete flooring.

COAT IT

A self-priming polyurea or polyaspartic basecoat is applied to securely bond to the floor to ensure the coating won’t chip or peel.

FLAKE IT

A polymer flake is generously hand broadcast providing even color & texture to the floor.

SCRAPE IT

Excess flake is scraped and vacuumed off the floor to prepare it for the final coat.

SEAL IT

Finally, we apply a UV stable polyaspartic topcoat. Your resistant new floor will be ready for light foot traffic after 12 hours.

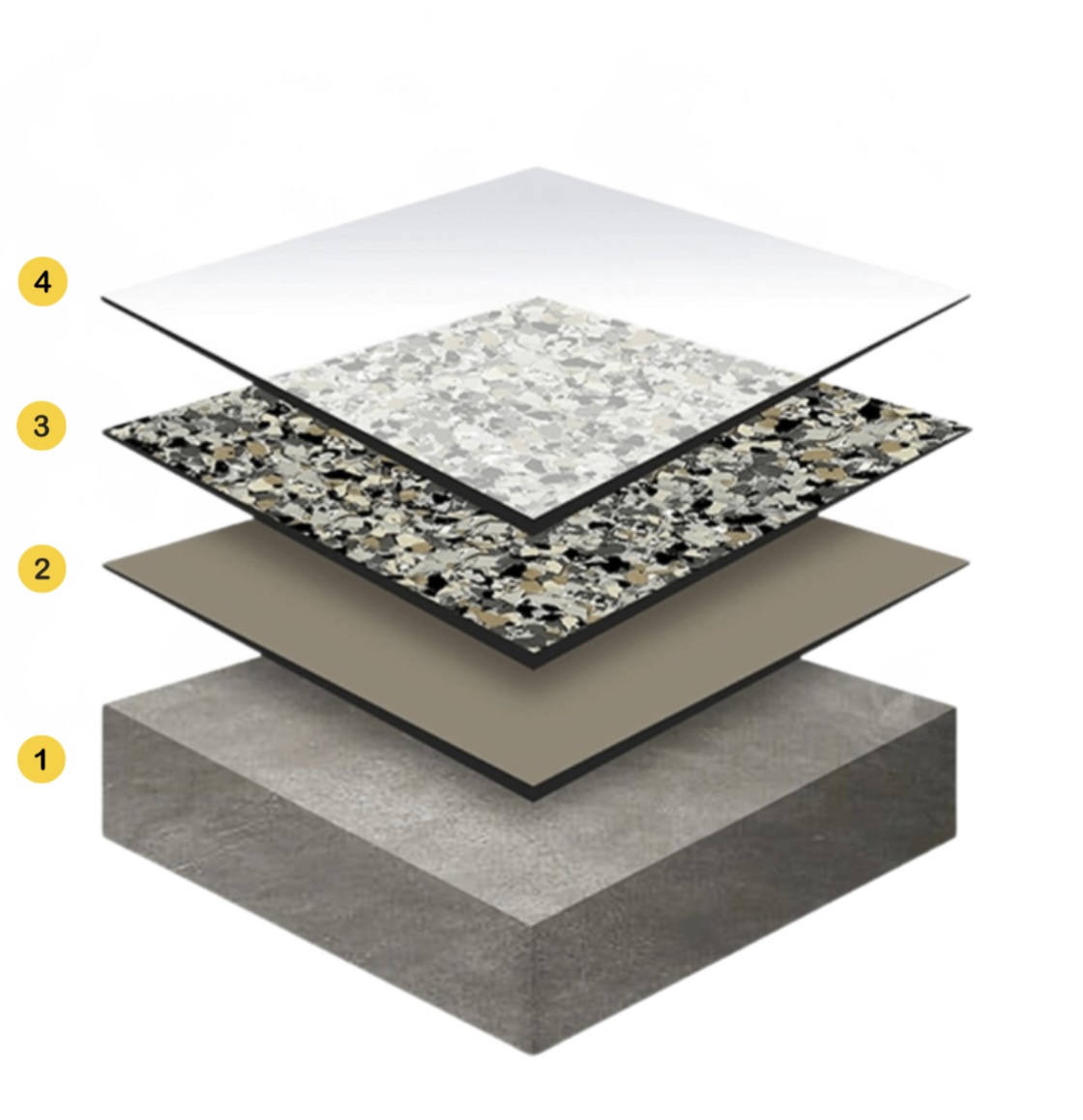

Our Proven Concrete Coating Process

1. Concrete (CSP-3)

This is the foundational substrate. The surface is mechanically profiled to CSP-3 (Concrete Surface Profile 3) for optimal coating adhesion.

Following the diamond profile grinding, we mend any existing cracks or pitting in the concrete to ensure a smooth and durable base.

2. Basecoat

A strong polyurea or polyaspartic basecoat is applied to create a bond with the prepared concrete surface and act as the binder layer for decorative flakes.

Most of the time, we recommend a polyurea basecoat for its durability and excellent adhesion. In cases with moisture concerns, a contractor-grade moisture-vapor barrier epoxy may be used instead. A polyaspartic basecoat is also an option for specific project needs.

3. Flake Layer

Decorative vinyl flakes are broadcast into the wet basecoat. These provide texture, color, and slip resistance.

We offer 24 standard flake blends to choose from and can also accommodate custom blend orders to match your desired aesthetic.

→ Browse Our Flake Color Options4. Topcoat

A clear, durable polyaspartic topcoat is applied to seal in the flakes, add gloss, and protect against UV, wear, and chemicals.

We use a high-solids, UV-resistant polyaspartic topcoat that ensures long-lasting protection and a professional finish.

Having the right process in place for every aspect of our business is what makes us who we are

From answering phones in the office to shaking our customer’s hand after they give the thumbs up wrapping up a project, we have a specific process in place to ensure quality is NEVER sacrificed.

Serving Greater des moines

2665 SE Oak Tree Court

Suite 104

Ankeny, IA 50021