Garage Floor Coatings

Transform your garage with ultra-durable and stylish coatings

Bring REVIVAL to your Garage floor

Garages endure a lot of wear and tear from vehicles, tools, and heavy equipment, causing stains and cracks over time.

Revival Concrete Coatings’s our signature flake coatings offer a superior alternative to epoxy. With a 15-year residential warranty and one-day installation, our coatings ensure long-lasting, resilient floors.

Some Recent Garage Projects

Why Revival Concrete Coatings?

Customized Solutions

We tailor every project to meet the needs of your home or business. This ensures the final result aligns with your vision and functional requirements.

Industry Leader

We are at the forefront of the coatings industry and consistently adopt the latest technologies and best practices to deliver superior results.

Trusted By The Community

We’ve earned a strong reputation in Iowa with thousands of satisfied customers and 200+ verified Google reviews for quality and reliability.

Certified and Trained

We are Sherwin Williams High Performance Flooring Certified and we use a highly trained in-house team for all installations. This ensures consistent quality and accountability.

Clear Communication

Our mission is to provide the highest quality coatings with the best customer service. Our job is to ensure you have clear communication and peace of mind from start to finish when you choose Revival.

Versatile Expertise

We have deep experience completing both commercial and residential projects with the capability to handle your project with precision.

Benefits of A Garage Floor Coating

Our garage floor coatings resist peels, chips, fading, and is 4x stronger than epoxy. With our concrete flooring, your garage floor will withstand the pressure and weight of your vehicles and heavy equipment for at least 15 years! Learn more about the benefits in this video.

With our coatings, you have access to multiple decorative options. Check out our gallery to see some of the most recent projects. You can also coat your verticals and stairs for a beautiful finish.

Our polyaspartic topcoat delivers excellent traction with our our slip-resistant additives. These additives provide extra grit through out the coating for enhanced texture.

Garage floors often get exposed to brake fluid, oil, dust, grime, chemicals, anti-freeze, and other substances that leave stains, not to mention slick spots.

With just soapy water, you can easily clean your polyaspartic garage floor coating to make it look like new.

Concrete coatings elevate the value of your space by enhancing durability, improving aesthetics, and creating a cleaner, more professional look that stands the test of time. The investment may pays dividends later, especially if you consider the protection of your concrete from cracks and pitting.

Why Polyaspartic Garage Floor Coatings are Better Than Epoxy

Our polyaspartic garage floor coatings are superior to traditional epoxy, offering unmatched durability, chemical resistance, and faster curing times. They are customizable, UV-resistant, and provide a flexible, cushioned layer that absorbs impact and prevents yellowing. Perfect for upgrading any home or business garage, our coatings also feature antimicrobial properties, ensuring a safe and long-lasting finish.

Our Process

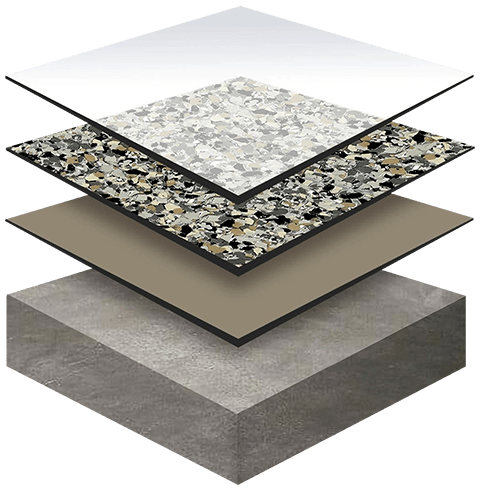

Concrete Coating System: Layer Overview

1. Concrete (CSP-3)

This is the foundational substrate. The surface is mechanically profiled to CSP-3 (Concrete Surface Profile 3) for optimal coating adhesion.

2. Basecoat

A strong polyurea or polyaspartic basecoat is applied to create a bond with the prepared concrete surface and act as the binder layer for decorative flakes.

3. Flake Layer

Decorative vinyl flakes are broadcast into the wet basecoat. These provide texture, color, and slip resistance.

4. Topcoat

A clear, durable polyaspartic topcoat is applied to seal in the flakes, add gloss, and protect against UV, wear, and chemicals.

Frequently Asked Questions

Find answers to commonly asked questions about concrete floor coatings. See video answers to our FAQs HERE.

OUR FREQUENTLY

ASKED QUESTIONS

Our polyurea and polyaspartic floor coatings are a concrete resurfacing option that is installed over existing concrete floors for both interior and exterior concrete. All of our coatings are installed by hand, thus giving our clients a true, one-of-a-kind floor. We install a wide range of flooring systems such as: solid color, flake, quartz, and grind and clear floors.

Clients have the ability to customize any coating with our various color options and design techniques. Concrete coatings are used not only in residential, but industrial and recreational settings as well. Revival Concrete Coatings uses only the highest quality, industrial products on the market to ensure every customer is getting the best value.

Each project is customized to your particular concrete flooring needs. Every job we do is different because we offer different types of coatings and finishes. In addition, each project can look different based on the repairs required to concrete. We will work with you to develop a free estimate keeping your budget in mind.

If using 100% solid polyurea, your floor will be cured and walkable in 12 hours. You can return to full heavy traffic after 24-36 hours depending on the temperature the floor was installed in.

We start every project by first preparing the concrete for our products. It is imperative that we have a fresh concrete surface before installing our concrete coatings on your project – this will allow our products to have only the BEST mechanical bond.

We spend approximately 33% of the project prepping your floor by diamond grinding with our 800 lb Lavina Grinder! Most contractors will come in and just acid wash or not even prep your floor – we get calls all the time about botched installs with customers asking if we can save their project; we must start fresh every time.

If you follow our maintenance and cleaning guidelines, you should not have to worry about resealing the concrete floor coating.

No worries, we are experts in repairing existing problem areas of concrete. In some cases we have been found to be a cheaper alternative over tearing out and replacing existing slabs of concrete. Once we have saved your concrete we then install our decorative designs to hide the flaws and repairs.

Sweeping takes care of most messes. If there is mud or chemicals you can mop them with any household soap and warm water. Dawn or SimpleGreen work great! If chemicals are spilled on the floor, wipe them up as soon as you notice them.

Floor coatings are extremely resistant to most hazards, including cleaners, gas, oil, transmission fluid, and even most industrial chemicals. Although our coatings are chemical resistant, you will still need to wipe up any chemical spills as soon as you notice them.

Polyurea is useful for concrete floors, as it quickly and strongly bonds to concrete while providing a smooth, virtually impermeable surface that protects the floor from impact, water damage, chemicals, heat, and sunlight.

Residential floors come with a 15 year warranty and commercial floors have a 5 year warranty.

Each project is customized to your particular concrete flooring needs. Every job we do is different, because we offer different types of coatings and finishes. We will work with you to develop a free estimate keeping your budget in mind.

We use the highest quality materials in our polyaspartic floor coatings and we’ve perfected our application process to make the concrete coating permanent. Once completely cured and adhered, the concrete coating is meant to last as long as the substrate it’s adhered to.

Polyaspartic Floor Coatings dry more quickly than Epoxy Floor Coatings, and the finish is also more durable. Our floor concrete coating finishes are also more slip-resistant and will not discolor like some Epoxy Floor Coatings.

Our flooring cures within a few hours, however our team of professionals recommends waiting at least 4-6 hours before walking on your brand new concrete coated flooring. After 12 hours, you can begin moving lightweight objects onto the flooring, like light patio furniture. We recommend waiting a full 24 hours before moving anything heavy back into the area where we’ve applied the coating (your car, heavy equipment or furniture etc.).

It sure won’t! Our concrete floor coverings will not yellow or discolor, because they are UV stable. This one of the many benefits of using Polyurea or Polyaspartic floor coatings.

If you follow our maintenance and cleaning guidelines, you should not have to worry about resealing the concrete floor coating. We offer a professional grade cleaner that will easily remove stains or tire marks, but will also preserve the life of your concrete coating topcoat.

We’ve perfected our 6-step application process, so most typical projects take between 5-10 hours depending on the square footage. We pride ourselves in a one-day application, and will do everything possible to stay within that time frame. Rainy weather can delay the project, but it is rare.

You can clean our concrete coatings with typical sweeping, mopping or steaming, and hoses. We offer maintenance services should your concrete flooring ever need cleaning, however you can also use non-abrasive cleaners, like CLR, to remove grease or other stains.

TAGG’s concrete coatings are oil resistant as well as moisture resistant.

Bayer Material Science first developed Polyaspartic coatings in the 1990’s to protect steel bridges and infrastructure from rusting and corrosion. It has since been modified for different applications, once being durable concrete flooring coatings.

Polyaspartic Concrete coating is another name for Aliphatic Polyurea, which is a hybrid material consisting of ester and other materials. It was originally developed to coat metal bridges. It was later used to coat concrete flooring due to its durability and moisture resistance. Polyurea is also used to coat truck bed liners.

They sure can! We offer wonderful solutions for driveways, patios, and even the area around the pool. Our coatings are all UV stable, which will help prevent discoloration or flaking.

Polyaspartic flooring coatings can be used in a variety of environments. The durability, slip resistant finish is fantastic for any industrial setting, storefronts, patios, or even driveways or garages.

We have perfected a six step process for applying Polyaspartic Floor Coatings that involves prepping the floor, basecoating, applying chips, scraping the chips, and applying the clear UV protective clear coat.

You can! Polyaspartic floor coatings are safe to apply in temperatures as cold as -40 degrees.

Our Polyaspartic Floor Coatings are engineered to rapidly cure, and can be dry in a matter of a few hours! However, we recommend waiting at least 5-6 hours before walking on newly applied coating and 24 hours before moving heavy objects back onto the flooring.

Installing Polyaspartic Floor Coating correctly is critical to the appearance and durability of your flooring. Hiring a professional is the best way to ensure that your flooring will look amazing and last a lifetime! Our team at TAGG Concrete Coatings is certified in Polyaspartic Floor Coating installation and have many years of experience.

It is! Polyaspartic floor coatings are specially formulated for their incredible adhesion properties. If you have existing patches of epoxy coating, our team can sand it down, vacuum, and wipe down the area with a solvent. Once prepped, we will apply your new, superior, Polyaspartic Floor Coating

Serving Greater des moines

2665 SE Oak Tree Court

Suite 104

Ankeny, IA 50021