The Complete Guide to Garage Floor Coating in Des Moines: What Every Iowa Homeowner Needs to Know

If you’ve ever walked into a neighbor’s garage and thought, “How does that floor look so good?” — you’re not alone. Garage floor coatings have become one of the most popular home improvements in the Des Moines metro, and for good reason: they protect your concrete, resist stains and chemicals, and transform an ordinary garage into a space you’re proud to show off.

At Revival Concrete Coatings, we’ve completed hundreds of garage floor coating projects across central Iowa. This guide covers everything you need to know — from the different types of coatings to what separates a great installation from one you’ll regret in two years.

Why Your Concrete Garage Floor Needs Protection

Bare concrete is porous. That means every oil drip from your car, every road salt tracked in from Iowa winters, and every chemical spill slowly works its way into the slab — causing staining, cracking, and degradation over time. A quality garage floor coating creates a sealed, impermeable barrier that’s dramatically easier to clean and far more durable.

Beyond protection, a coated floor simply looks better. Whether you’re selling your home, converting your garage to a workspace, or just tired of a dingy gray slab, the right coating makes a huge difference.

Garage Floor Coating vs. Garage floor epoxy: What's the difference?

This is one of the most common questions we hear. Many homeowners use “garage floor epoxy” and “garage floor coating” interchangeably, but they’re not quite the same thing.

Traditional Garage Floor Epoxy

Epoxy is a two-part system — a resin and a hardener — that chemically bonds to concrete. Standard epoxy products have been popular for decades and offer good adhesion and chemical resistance. However, traditional epoxy can yellow over time with UV exposure, and cheaper DIY epoxy kits often fail within a few years in Iowa’s climate because they can’t handle the freeze-thaw cycles and temperature swings our winters deliver.

Polyaspartic and Polyurea Coatings

These are the professional-grade coatings that have largely replaced basic epoxy in high-quality installations. Polyaspartic and polyurea coatings cure faster, handle temperature extremes better, offer superior UV stability (no yellowing), and are more flexible — which matters a lot on concrete that expands and contracts with Iowa seasons. At Revival Concrete Coatings, we use commercial-grade polyaspartic systems that outlast traditional epoxy by years.

The Bottom Line

When Des Moines homeowners ask us for “garage floor epoxy,” what they usually really want is a durable, professional coating that looks great for the long haul. That’s exactly what we deliver — with a system engineered for Iowa’s climate, not a one-size-fits-all DIY product.

| Feature | Epoxy | Polyurea / Polyaspartic |

|---|---|---|

| Cure time | Slower (can take 24–72 hrs) | Very fast (sometimes within hours) |

| Flexibility | Rigid, good adhesion | More flexible — better for movement or temperature shifts |

| UV / yellowing | Can yellow over time if not UV-stable | Better UV stability when formulated and applied properly |

| Chemical / stain resistance | Good, but more vulnerable to harsh chemicals | Excellent resistance to oils, solvents, acids |

| Cost | Generally lower upfront | Higher material cost |

| Best use cases | Basements, garages, indoor spaces | Outdoor patios, driveways, commercial / industrial floors |

The Two types of Garage floor coatings (and which is right for you)

- Full Broadcast Chip (Flake) Systems

This is the most popular choice for residential garages. Decorative vinyl flakes are broadcast into the base coat, creating a terrazzo-like appearance that hides imperfections, provides texture for slip resistance, and comes in dozens of color blends. It’s durable, easy to clean, and gives your garage a high-end showroom look. This is what you typically see in the “after” photos that make you want to redo your garage.

Solid Color Coatings

A single-color coating offers a clean, modern look — popular for workshops, commercial spaces, and homeowners who prefer a minimal aesthetic. A topcoat seals and protects the surface. Without decorative chips, surface imperfections in the concrete may show through more, so proper prep work is even more critical.

What to expect from a professional garage floor Coating installation

This is where the difference between a professional installation and a DIY kit becomes most apparent. A properly installed coating starts long before the first drop of material hits the floor.

Step 1: Concrete Assessment

We test moisture levels, check for existing sealers or contaminants, and inspect for cracks, spalling, or other damage. Concrete that isn’t properly prepared will cause even the best coating to delaminate and peel — this is why most DIY garage floor kits fail.

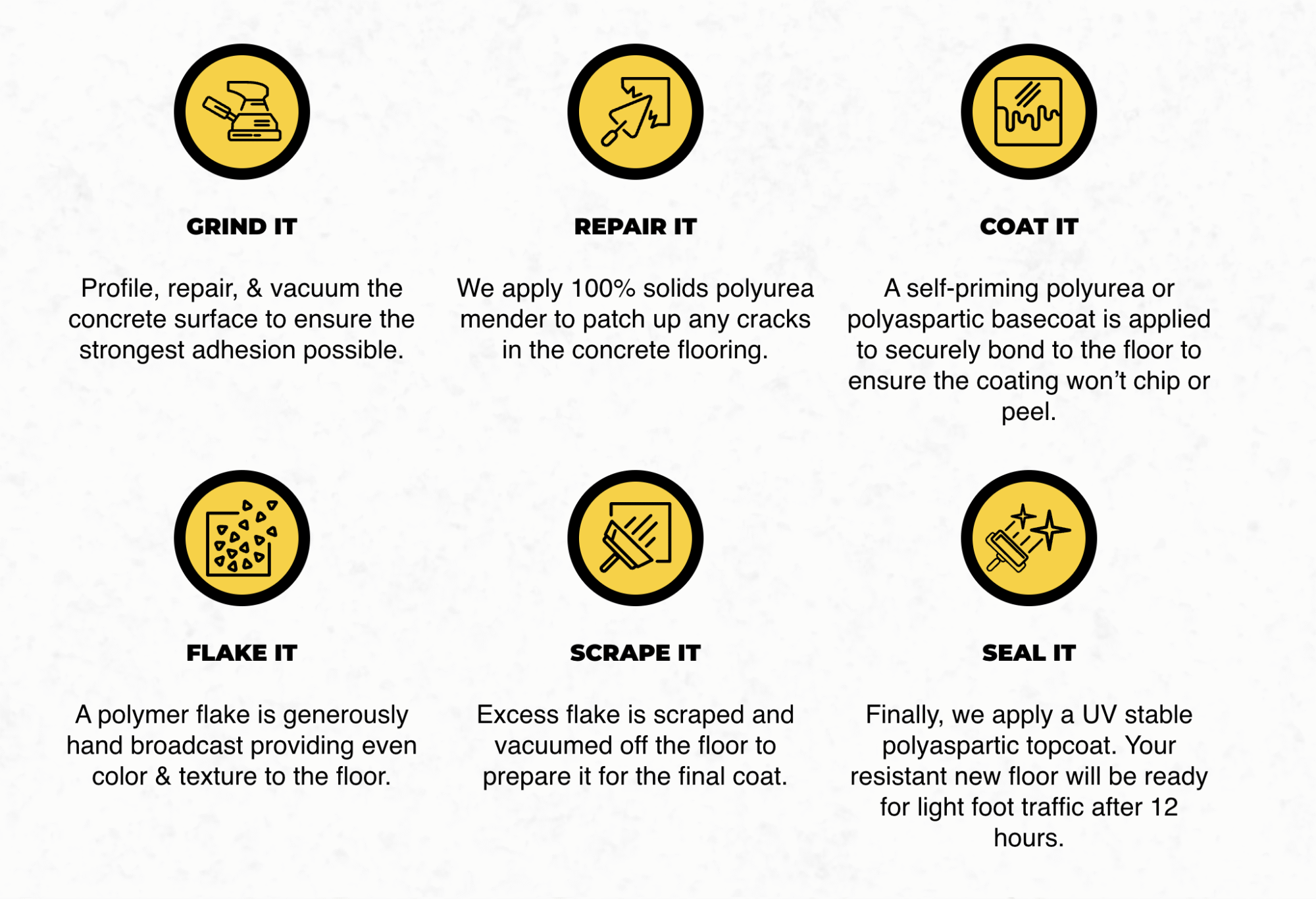

Step 2: Diamond Grinding

Unlike acid etching (a common DIY method), professional diamond grinding mechanically profiles the surface of the concrete, opening the pores and ensuring maximum adhesion. This step alone separates professional-grade results from home improvement store kits.

Step 3: Crack and Spall Repair

Any cracks, chips, or low spots are filled and feathered. This gives you a smooth, even surface to coat and prevents issues from telegraphing through the finished floor.

Step 4: Coating Application

The base coat, chip broadcast (if applicable), and topcoat are applied in sequence, with appropriate cure time between layers. The final topcoat provides the chemical resistance and UV stability that makes the floor last.

Step 5: Quality Inspection and Walk-Through

We don’t consider the job done until you’ve seen the final result and you’re satisfied. We walk you through care and maintenance so your floor stays looking great for years.

How long does a garage floor coating last?

A professionally installed polyaspartic or polyurea coating — properly maintained — should last 15–20+ years. DIY epoxy kits? Often 2–5 years before peeling, yellowing, or hot tire pickup (where your tires literally pull the coating off the floor on a hot summer day) begins.

The warranty matters too. At Revival Concrete Coatings, we stand behind our work. Ask any contractor you’re evaluating what their warranty covers and for how long.

How Much does a floor coating cost in des moines?

Pricing for garage floor coating in the Des Moines metro area varies based on the size of the garage, the condition of the concrete, the coating system chosen, and the amount of prep work required. As a general range:

- Single-car garage (approximately 250 sq ft): $1,200 – $1,800

- Two-car garage (approximately 500 sq ft): $2,000 – $3,500

- Three-car or large garage: $3,500+

Be cautious of quotes significantly below these ranges — they almost always reflect shortcuts in prep work or inferior materials. The most expensive part of a lasting garage floor coating is the labor to properly prepare the surface. If a company skips that, you’re paying for a coating that won’t last.

We provide free, no-obligation estimates for any garage floor coating project in central Iowa.

why des moines homeowners choose revival concrete coatings

With dozens of garage floor companies near you to choose from, here’s what sets Revival apart:

- 230+ five-star Google reviews from real Iowa homeowners — more than any competitor in the market

- Commercial-grade polyaspartic systems built for Iowa’s climate, not cheap DIY products

- Certified installers trained in proper concrete preparation and diamond grinding

- Transparent pricing with no hidden fees

- Locally-owned and operated — we stand behind every floor we install. We’re small enough to know you and big enough to serve you.

We’ve built our reputation one garage at a time across Des Moines, Ankeny, West Des Moines, Urbandale, Johnston, and surrounding communities. When you’re searching for floor coating companies near you, we’d love the chance to earn your business.

other frequently asked questions

How long does the installation take?

Most standard two-car garages can be completed in a single day with our fast-cure polyaspartic systems. You’ll typically be able to walk on the floor within 12 hours and drive on it within 24 hours.

Can you coat a garage floor in cold weather?

Traditional epoxy has temperature restrictions that make winter application challenging. Our polyaspartic coatings can be applied in a wider temperature range, making year-round installation possible in Iowa — though we do require the concrete to be above 35°F at the time of application.

Does the floor get slippery when wet?

Without texture, coated floors can be slippery when wet. We incorporate texture additives into our topcoats as a standard practice to provide slip resistance — especially important in a garage where you may be walking in with wet or snowy boots.

What do I need to do to prepare for my installation?

Remove vehicles, tools, and anything stored on the floor. We handle everything else — including moving appliances if needed. We’ll give you a detailed preparation checklist when you book your appointment.

Will the coating hide cracks in my concrete?

Minor surface cracks and imperfections are filled during the prep process and won’t show through the finished coating. Structural cracks (cracks that move or have significant displacement) can be a different matter — we’ll assess these during our free consultation.

Ready to transform your garage floor?

Whether you’re searching for garage floor coating, garage floor epoxy, or simply the best floor coating companies near you in Des Moines — Revival Concrete Coatings is ready to help. Our team will assess your concrete, recommend the right system for your goals and budget, and deliver results that last.